Stack Loader

A Lightweight, Compact, and High-Speed Vertical Storage System

Features & Benefits

- point 1

Lightweight and Compact Design

With a payload capacity of 25 kg, the system is lightweight and relatively compact.

- point 2

Flexible Storage and Retrieval

Products or items can be freely selected, stored, and retrieved via the control panel. No special licenses are required, making it easy for anyone to use.

- point 3

Low Maintenance

and High DurabilityCable-free operation and an automatic lubrication system minimize maintenance needs while ensuring excellent durability.

- point 4

Integrated Inventory Management

with Production LinesThe system can seamlessly connect to production lines for efficient inventory management.

Applicable Workpieces

The system is compatible with workpieces such as cardboard, containers, and boxes with consistent shapes.

Main Components

NC Controller-Based Control

Precision positioning is enabled through NC controller-based operation. The interface features a touch panel, allowing operators to monitor conveyor line activity at all times via an original operation monitor screen.

The teaching interface supports both manual input and a direct teaching function, allowing loader positions to be input without manual calculations. The handheld operation box can handle up to 16 points of selection, offering 0.01 mm unit movement control through axis selection.

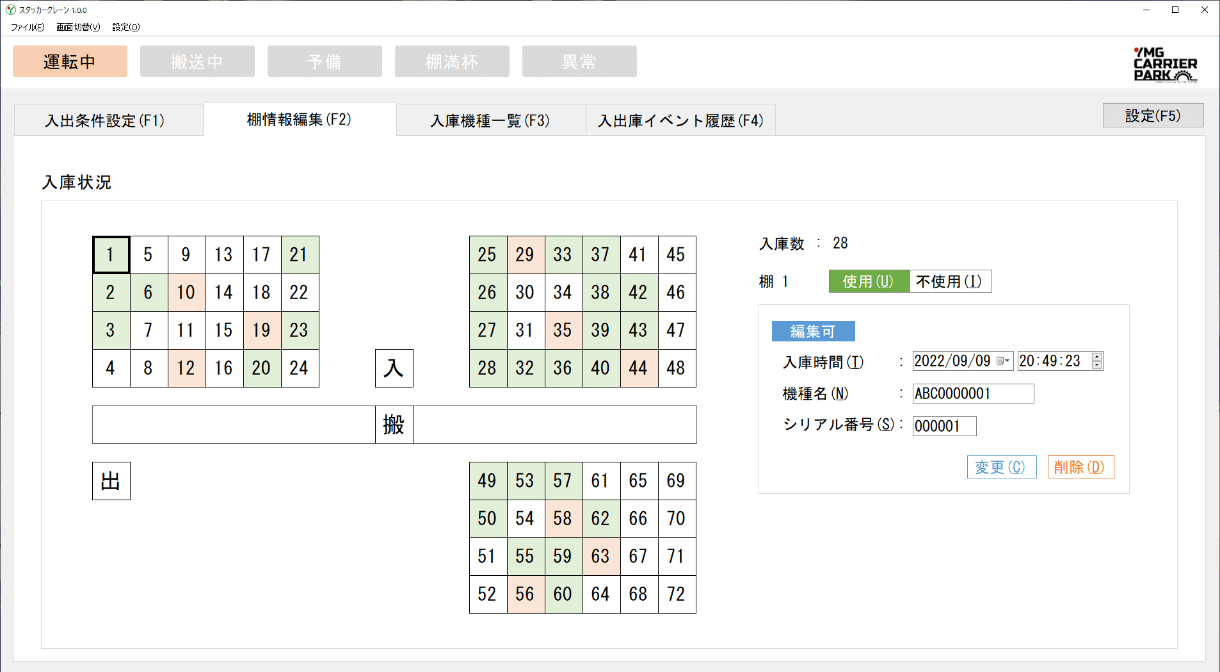

Manage Operations with a Dedicated Computer

A dedicated computer allows for efficient monitoring and management of storage and retrieval activities. The management interface provides an overview of empty shelves, storage status, and updates event logs for every stored and retrieved item.

This is YMG’s original Stack Loader management system, offering:

Storage and Retrieval Status Screen

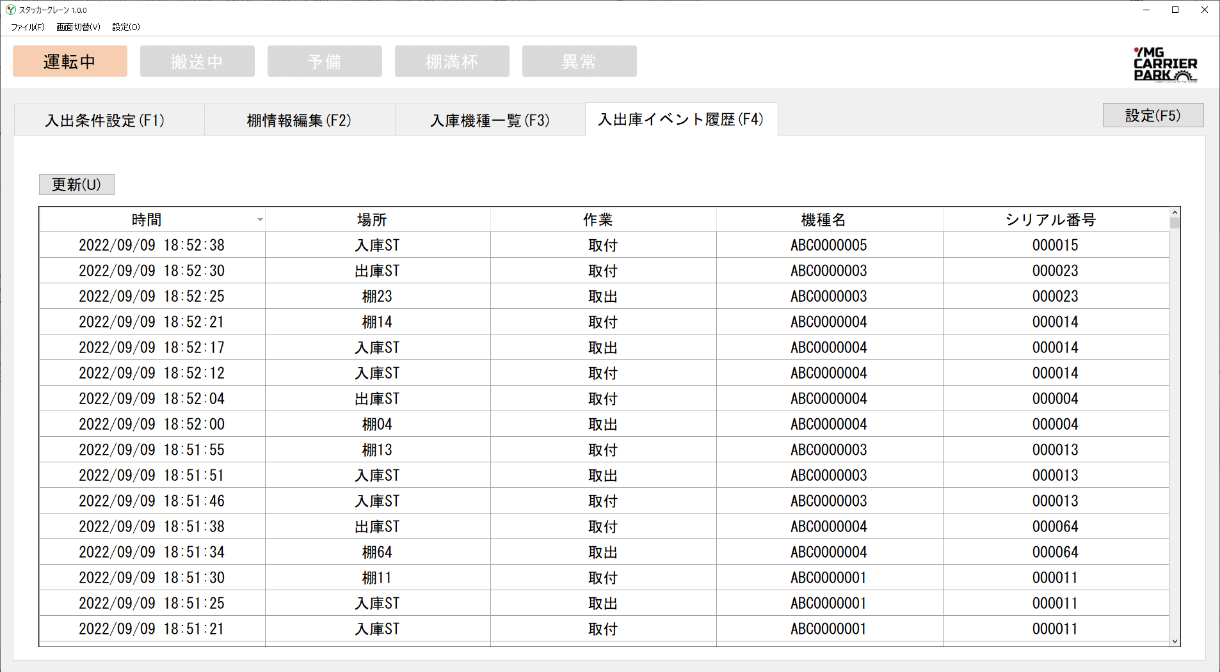

Event Log Screen for Storage and Retrieval

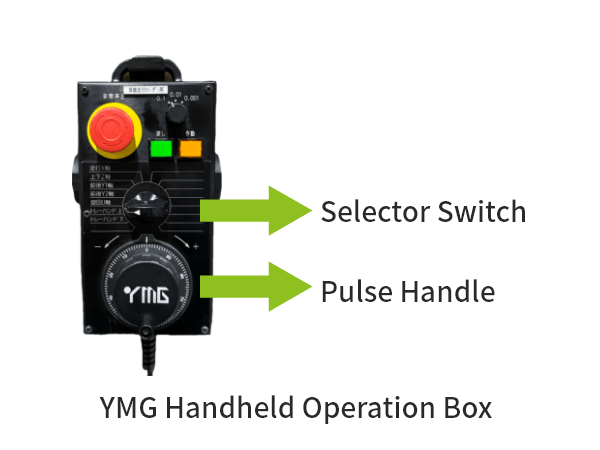

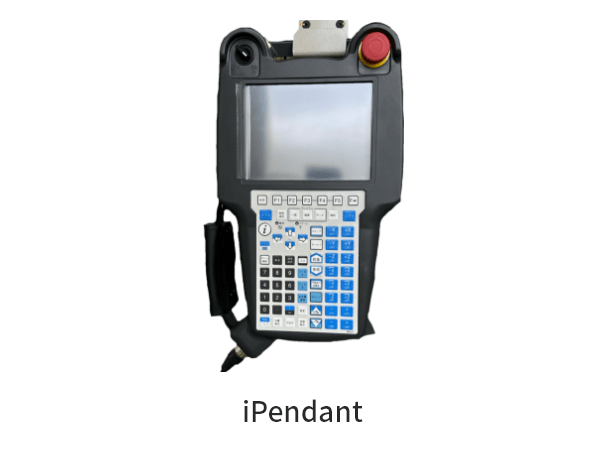

Handheld Operation Boxes

The type of handheld operation box can be customized to meet customer requirements. If no specific request is made, the standard YMG handheld operation box will be provided.

Equipped with a pulse handle for axis-specific operations in increments ranging from 0.1 mm to 0.001 mm. Up to 16 operation points can be assigned using a selector switch. Comes with a 5-meter coiled cord.

Axis operations are selectable via buttons, with the axis position displayed on the screen. Standard cable length: 7 meters.

Custom handheld operation boxes can be provided as optional configurations.

Similar to BOX 2, this configuration allows axis operations via buttons with position display functionality. Standard cable length: 7 meters.

Case Studies

Stack Loader

A lightweight and compact high-speed moving automated warehouse system.

Any item or product can...

Main Standard Specifications

- Item

- Standard Specifications

- X-Axis

(Travel) Motor Model

α iS 40/4000-B S <FANUC>

Speed

MAX300m/min

Stroke

24m

(Expandable up to 100 m)*1- Y-Axis

(Front/Back) Motor Model

α iS 4/5000-B S <FANUC>

Speed

720mm(MAX735mm)

Stroke

720mm(MAX735mm)

- Z-Axis

(Up/Down) Motor Model

α iS 30/4000-B SB <FANUC>

Speed

MAX100m/min

Stroke

600mm(MAX620mm)

- Rotating Axis

Motor Model

-

Speed

-

Reduction Ratio

-

Rotation Angle

-

- Item

- Standard Specifications

- Hand

Type

Shuttle Fork System

Drive Method

Servo Motor

Payload Capacity

MAX 25 kg

- Lubrication

X, Y, and Z-axis guides and racks: Automatic lubrication

- Storage Unit Type

Plastic Containers *2

- Storage Unit Size

L390×W590×H200 *2

- Additional Features

Fully electric (airless operation)

Cable-free travel section using optical data transmission

- Power Supply

Trolley Reel

- Controller

Q05UDVCPU <Mitsubishi Electric>

FANUC Series 35i-MODEL B <FANUC>

*1: For Optical Data Transmission System Ver.1. For Ver.2, expansion up to 200 m is supported.

*2: Other specifications and sizes are available upon consultation.

Contact

Free Quote

We provide estimates tailored to your company’s requirements.

Automation Consultation

Feel free to reach out to us anytime for assistance.