Gantry Palletizer

A Palletizing System Integrating Both Palletizing and Depalletizing Functions

Features & Benefits

- point 1

Automatic Position

and Height DetectionEquipped with a camera installed on the hand, the system automatically detects tray position and height for efficient unloading. With a payload of 25 kg, the system remains lightweight and compact.

- point 2

Tray Transfer Function

for Up to 3 LevelsBy adding a multi-level unit to a standard roller conveyor, the system can transfer up to three stacked trays at once.

- point 3

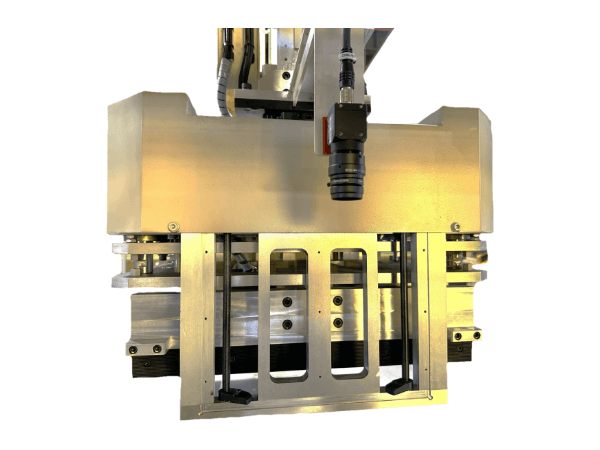

Efficient Loading in Tight Spaces

The use of a specialized hand allows for efficient pallet loading, even in narrow tray gaps.

- point 4

Space-Saving

Simultaneous OperationsWith integrated palletizing and depalletizing functions, the system enables space-saving installation and simultaneous operation.

Applicable Workpieces

The system is compatible with workpieces such as cardboard, containers, and boxes with consistent shapes.

Main Components

NC Controller-Based Control

Precision positioning is enabled through NC controller-based operation. The interface features a touch panel, allowing operators to monitor conveyor line activity at all times via an original operation monitor screen.

The teaching interface supports both manual input and a direct teaching function, allowing loader positions to be input without manual calculations. The handheld operation box can handle up to 16 points of selection, offering 0.01 mm unit movement control through axis selection.

Position Correction Camera

Camera: Position correction camera

Monitor: 2D image processing monitor

The camera detects and corrects positional deviations in the X and Y axes. If a container is within the designated range, the system automatically performs palletizing and depalletizing.

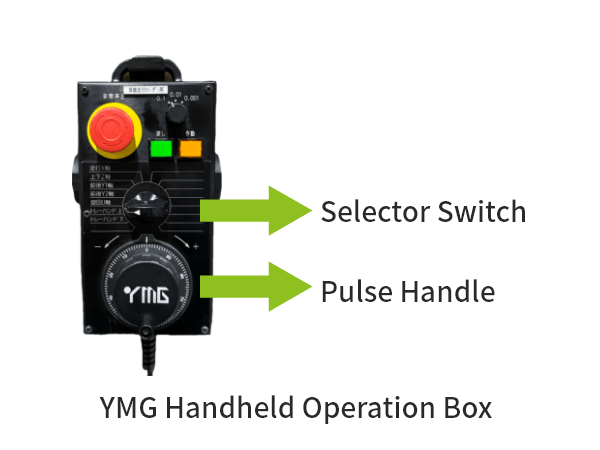

Handheld Operation Boxes

The type of handheld operation box can be customized to meet customer requirements. If no specific request is made, the standard YMG handheld operation box will be provided.

Equipped with a pulse handle for axis-specific operations in increments ranging from 0.1 mm to 0.001 mm. Up to 16 operation points can be assigned using a selector switch. Comes with a 5-meter coiled cord.

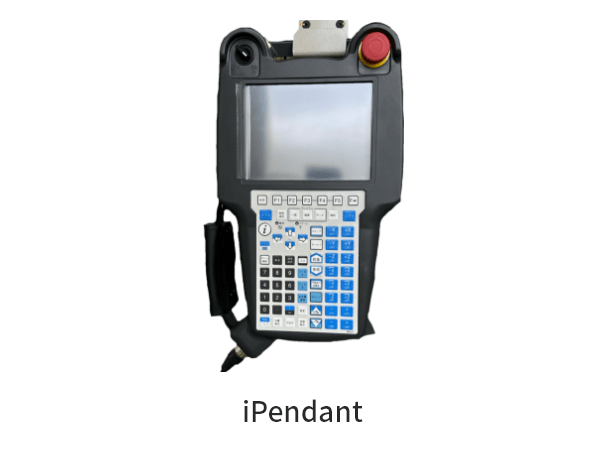

Axis operations are selectable via buttons, with the axis position displayed on the screen. Standard cable length: 7 meters.

Custom handheld operation boxes can be provided as optional configurations.

Similar to BOX 2, this configuration allows axis operations via buttons with position display functionality. Standard cable length: 7 meters.

Case Studies

Gantry Palletizer

A palletizer device that integrates both palletizing and depalletizing functions.

The palletize...

Main Standard Specifications

- Item

- Standard Specifications

- X-Axis

(Travel) Motor Model

β iS 12/2000-B S <FANUC>

Speed

60m/min

Stroke

2851mm(MAX2871mm)

At one-side stopper position- Y-Axis

(Front/Back) Motor Model

β iS 12/2000-B S <FANUC>

Speed

60m/min

Stroke

1560mm(MAX1580mm)

- Z-Axis

(Up/Down) Motor Model

β iS 12/2000-B S <FANUC>

Speed

36.36m/min

Stroke

1360mm(MAX1380mm)

- Rotating Axis

Motor Model

β iS 1/6000-B S <FANUC>

Speed

30r/min(MAX181.82r/min)

Rotation Angle

110°(MAX300°)

- Item

- Standard Specifications

- Palletizer Hand

Type

Parallel Chuck System

Drive Method

Compressed Air

Payload Capacity

45kg

- Depalletizer Hand

Type

Inner Claw: Parallel Chuck System

Outer Claw: Link Hook SystemDrive Method

Compressed Air

Payload Capacity

45kg

- Lubrication

Automatic lubrication for X-Axis, Y-Axis, Z-Axis linear guides and racks.

- Controller

FANUC Series 35i-MODEL B <FANUC>

Contact

Free Quote

We provide estimates tailored to your company’s requirements.

Automation Consultation

Feel free to reach out to us anytime for assistance.